Did you know that the quality and suitability of the products in your maintenance/operations “toolbox” can actually have an enormous impact on productivity, equipment reliability, and overall costs? Below, learn about the Chesterton stand-out products that we recommend for primary maintenance and cleaning needs.

1. Equipment Disassembly

One of the most common products in the maintenance shop is a penetrating oil or a multi-purpose spray that is intended to be used to help in the removal of bolts and fasteners. Ideally, this oil should be highly concentrated and not contain harmful solvents and propellants (some oils have up to 80%). Two Chesterton products meet the highest standards of performance and safety.

Chesterton 706 Rustsolvo® (Bulk)

Chesterton 723 Sprasolvo® (Aerosol)

- Does NOT contain ketones, alcohols, acetone or aromatic compounds that are significant workplace hazards

- SLOW evaporation

- DEEP penetration

- Remain on the part for days, not seconds

2. Assembly & Bolt Tension

Proper gasket and packing seating stress is critical to seal internal pressure, to prevent blowby and to ensure VOC compliance. Bolts must be assembled and tensioned correctly using calibrated torque or tension tools. However often the accuracy of the thread paste / anti-seize is never questioned…yet it should be!

While a K(nut) factor is frequently expressed in the torquing calculations, you should always know the range or accuracy of that value for the anti-seize you are using. While an average K(nut) factor might be 0.16, a scatter of +/-10%, 15% or 20% can create a tension inaccuracy of 20, 30 or 40%.

Chesterton 783 ACR Anti-Seize

Chesterton 785/785 FG Parting Lubricants

- Composed of ultra-fine lubricating solids of 4-7 microns that fill in the smallest of surface asperities

- Ensure a smooth and accurate transfer of torque to tension

- Have ultra-fine solids that remain on the surface throughout heat cycling — permitting hot re-torqueing without thread galling

- Deliver a K(nut) factor scatter as low as +/-1.25% that ensures torqueing and tension accuracy

- Can be used reliably and predictably on threads, washers and under bolt heads and nuts

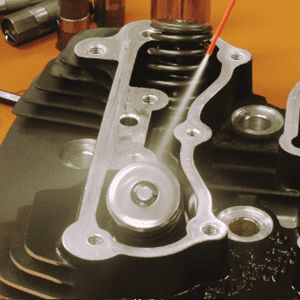

3. Sealing for Worn Flanges and Irregular Surfaces

Equipment sealing surfaces worn by corrosion, mechanical abuse, distortion and warpage makes gasket sealing difficult. This is further complicated when the sealing surfaces are dimensionally important such as for line bore equipment (Split Case Pumps, Gearboxes, Compressors and the like). When deviations exceed the compressive limit of gaskets, leakage can occur and equipment performance is compromised.

In critical industries the use of in-place machining and resurfacing are preferable to gasket dressing, shellacs, or compounds. While ideal, there are numerous conditions in which the use of a form-in-place gaskets can be used to fill in surfaces effectively.

Chesterton 860 Moldable Polymer Gasket

- A permanently elastic, non-adhesive polymer sealant that cures in place.

- Can be used in conjunction with conventional gasketing as a surface treatment on both sides of the gasket to fill in deviations and cure in place.

- Not an acetic acid curing RTV silicone; will not contaminate lube oil and process fluids with corrosive acidic by-products.

- Once cured, the 860 can seal up to 3000 psi hydraulic or fluid pressure.

- Ideal for sealing mechanical seals to rough stuffing boxes, casing halves on split case pumps, gearboxes and compressors, heat exchanger heads, tanks and storage vessels.

4. Thread and Pipe Sealing

We are all familiar with off spec, thin, paper like thickness and low density white sealing tape. Used by wrapping 5 to 8 times, this type of tape can shred, tear and leak. Often, this tape is replaced with curing pipe dope based on anaerobic sealants. While at first these seem adequate, in service they become brittle and crack under vibration, cannot be adjusted, and in hot surfaces lose 50% of their strength at 250F (120C) service. Leakage of air, oil and seal environmental control fluids are expensive and can impact plant reliability.

Chesterton 800 GoldEnd® Tape

- Heavy duty, high density, tear resistant and moldable

- Can handle a pH 0-14 and temperature exposures from -400F(204C) to 500F(260C)

- Performs under fluid pressure up to 10,000 psi (690 bar).

- Suitable for oxygen use

- For use on metal or plastic threads, pipes, or bolts.

5. Equipment Cleaning and Inspection

Cleaning and degreasing of critical motor, pump and machinery equipment allows for inspection and repairs to be done more efficiently. Cleaners should be free of hazardous, toxic solvents without compromising the ability to quickly and safely remove oil, grease, adhesives and other soils.

Chesterton 292 Precision Degreasing Solvent

- Safe for all metals and most plastics

- Contains no ozone-depleting chemicals

- Low odor; pleasant to use

- Low residue; evaporates cleanly

- NSF registered for use in Food, Beverage and Pharmaceutical applications