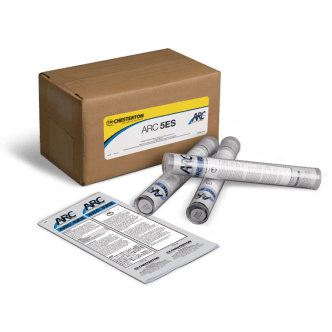

ARC 5ES Polymer Composite (Food Grade)

Rapid-Cure, “Putty” Grade Industrial Coating for Sealing Leaks 100% Solids, “2 in 1” emergency patch, and leak seal repair epoxy putty. ARC 5ES repair putty is designed to: Patch and seal leaks up to 3 mm (.125”) diameter Cure underwater and on damp surfaces Meet the requirements of NSF 61 for cold water service Easily apply …